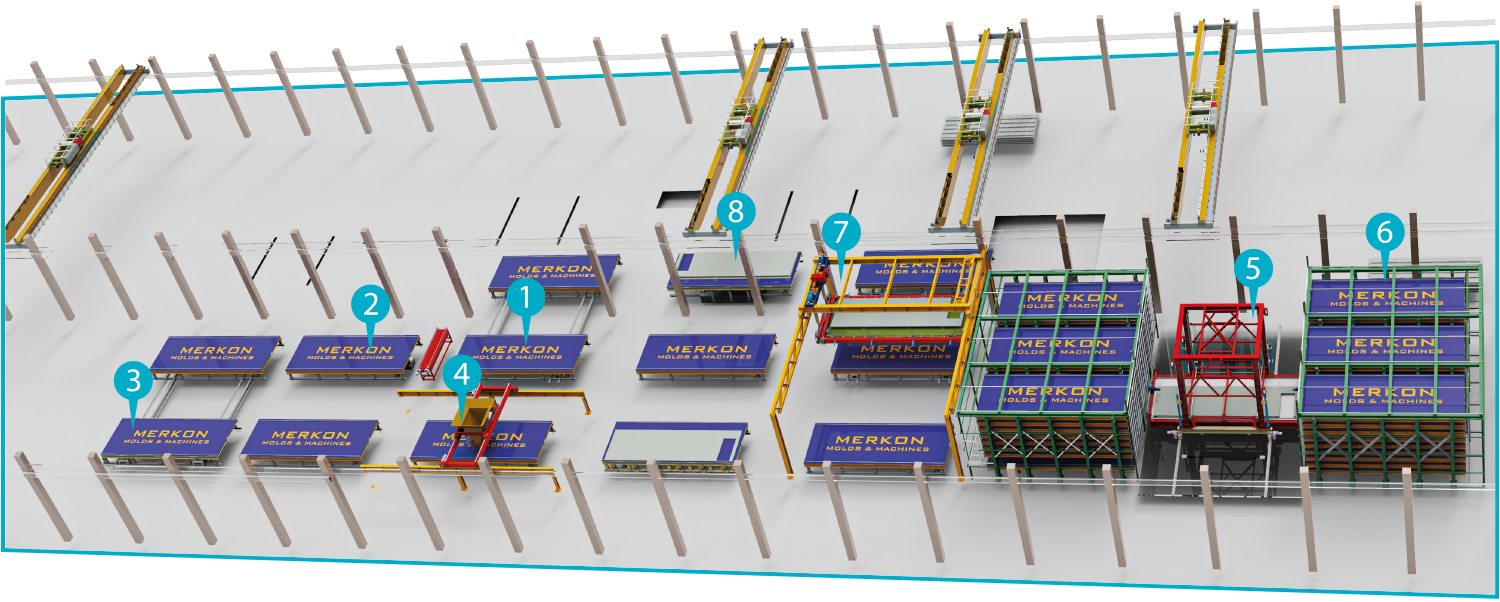

Isolated Double Wall /

Floor Slab Advanced Version

Precast

- Bed Cleaning&Checkup

- Mold Preparation

- Rebar Preparation

- 2 Axis Casting

- Casting Bed Elevator

- Curing Chambers

- Turning Machine

- Tilting&Storing Section

The system, which communicates completely electronically, ensures that all business processes are followed, there is no room for errors and the work remains optimized. Mold separators and iron reinforcements are placed in the places indicated by the laser. Precsion-filled molds are transported to the curing chambers for the required curing. Capacity is kept high by feeding more rooms with a single elevator. If it is an inner wall that dries out, it is left on its outer mate by the turning machine. Completed products are erected and transported to the stock area.

| PRODUCT DIMENSIONS | Max Lenght (m) | Max Width (m) | Max Thickness (cm) | m² on Pallet |

| SOLID WALL / SOLID SLAB | 9 | 3 | 15 | 27 |

| SANDWICH PANEL | 9,5 | 3,5 | 25 (5-6 concrete) | 33,25 |

| PRODUCTION CAPACITY | PALLETS PER HOUR | PER 20 HOUR DAY | DAILY YIELD m² (80% efficiency) | YEARLY YIELD (m²) (300 days) |

| DOUBLE WALL / INSULATED DW | 2 | 40 | 532 | 159600 |

| FLOOR SLAB | 2 | 40 | 1064 | 319200 |

| Auto Mesh DOUBLE WALL / INSULATED DW | 4 | 80 | 1064 | 319200 |

| Auto Mesh FLOOR SLAB | 4 | 80 | 2128 | 638400 |