Concrete

Block Machines

3036 Golden Features

Energy saving up to 67%

with R&D award-winning

Servo hydraulic system.

Versatile profitability with

multi-level, high-capacity

production.

Premium quality compaction

with steel vibrator table.

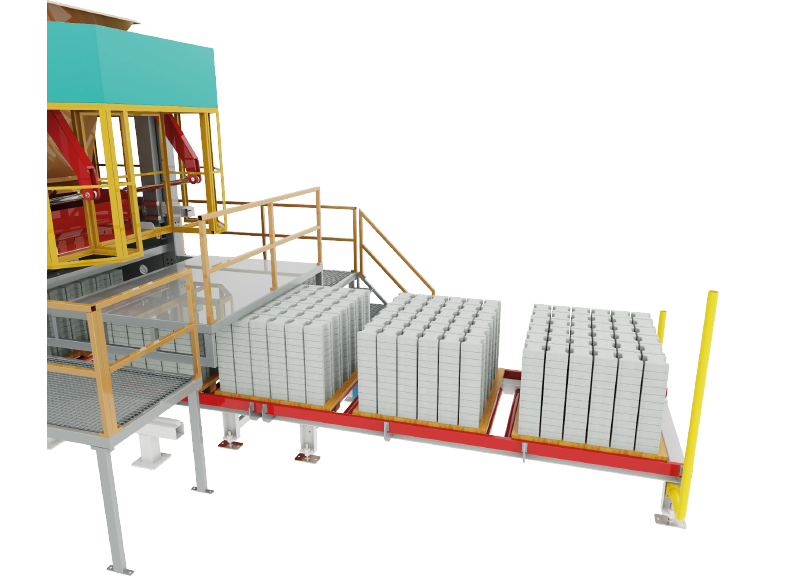

WAs a solution to meet high production needs with a low budget, the 3036 is the most modern example of the multi-layered production system that has left its mark in the recent past.

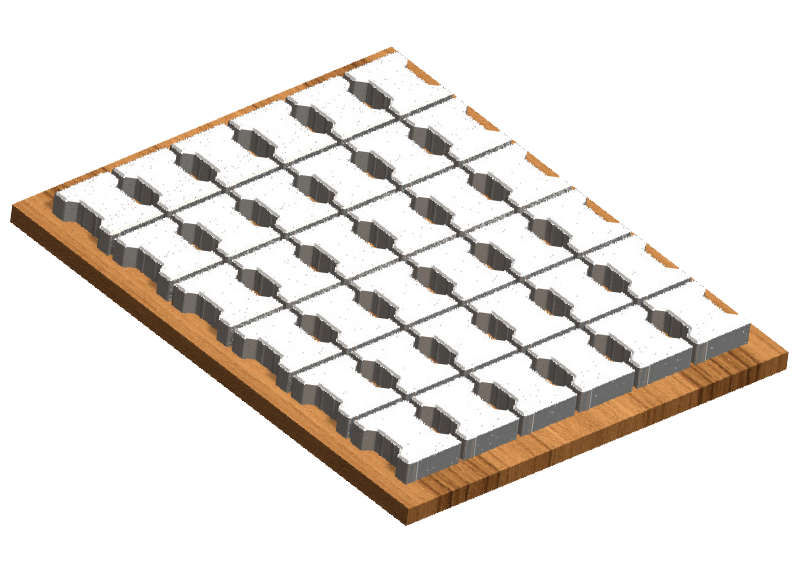

MUnlike single-layer machines, where each press is made on a pallet, the 3036’s pallet is not expected to transmit vibration to stone or withstand the abrasive effects of cement and moisture. Before each press, sand is laid between them so that the products do not stick completely, and the rows of products stacked on top of each other are taken to the area where they will dry on forklift compatible pallets. and machine line. The dried products are easily transferred to the shipping pallets with all kinds of holders. The emptied production pallets are sent to the machine for the next casting. And this simply completes the processing process. Thanks to its multi-layer production, pallet requirement amount of 3036 is 10%of single layer machines. This saves up to 90% of time and effort in handling. Considering its productivity and investment cost, it maintains its place in the sector as the most economical solution for high-volume projects.

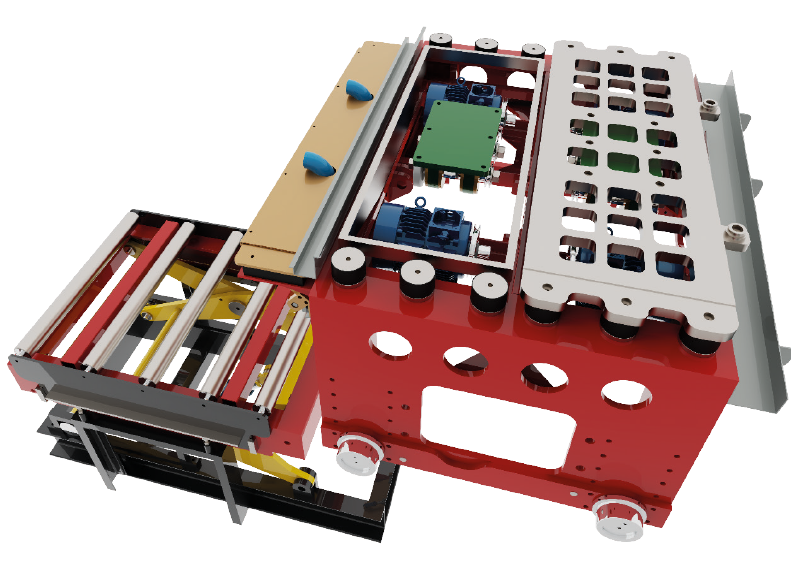

TECHNICIAL SPECIFICATIONS

| MERKON 3036 | Full Automatic |

| Production Time | 30 Sn. |

| Palet Size | 1150 x 1300 x 50 mm |

| Mold (Production) Area | 1 m2 |

| Minimum Product Height | 60 mm |

| Maximum Product Height | 300 mm |

| Total Power | 60 Kw. |

| Main Hydraulic Servo Motor | 150 Nm. |

| Auxiliary Hydraulic Motor | 7,5 Kw. |

| Main Vibrator | 2 x 28 Kn. |

| Top Vibrator | 1 x 18 Kn. |

| Operating pressure | 180 Bar. |

| Vibrator Table Control | Lazer |

| Pallet Dispenser Capacity | 10 Units |

| Rough Table Body | 1800 x 1600 x 20 mm |

| Thin Table Body | 800 x 1600 x 20 mm |

| Pallet Stacking Robot Control | Sensor |

Lowest investment/output rate considering the eliminated pallet cost due to multi-level production on a single pallet. Since introducion of multilayer Laser con- trolled precise and smooth movements. An awarded Servo pump application on hydraulic unit that ensures energy saving and quick system responses at all times. Simplified touch-screen control with user friendly interface.

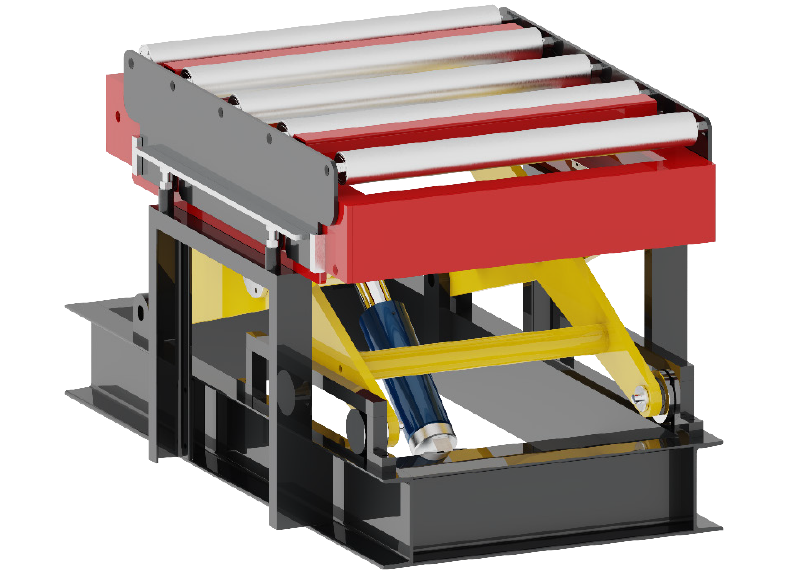

Production pallet elevator lifts the pallet up underneath the mold, so the concrete products are stripped on to it. After each layer of production elevator goes further down and less up, as per the product height.

Production pallet elevator lifts the pallet up underneath the mold, so the concrete products are stripped on to it. After each layer of production elevator goes further down and less up, as per the product height.

PAVING CAPACITY m²/h

| INSTALLMENT | PRESS AREA M² | YIELD M²/h | YIELD M²/ 3036 Shift |

| 3036 | 1 | 120 | 960 |

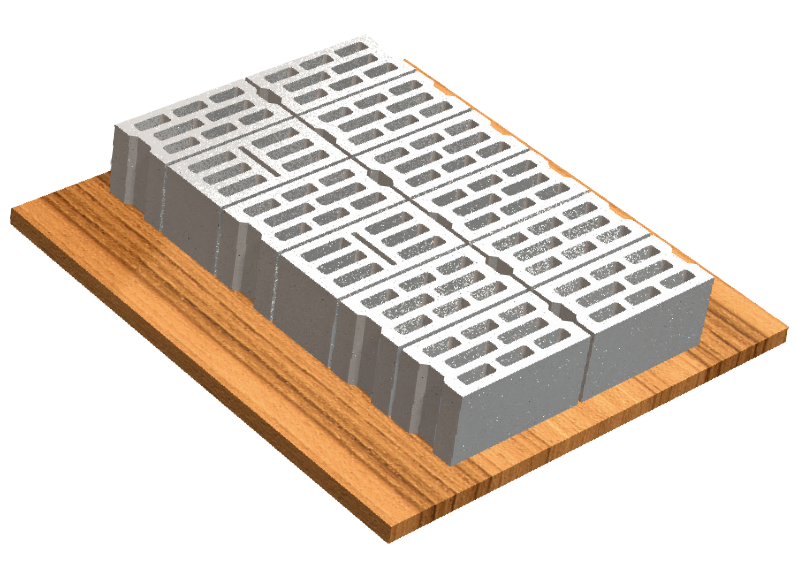

8" BLOCK (20x40x20)

| INSTALLMENT | BLOCKS PER PRESS | YIELD Pcs/h | YIELD M²/Shift |

| 3036 | 12 | 1440 | 11520 |

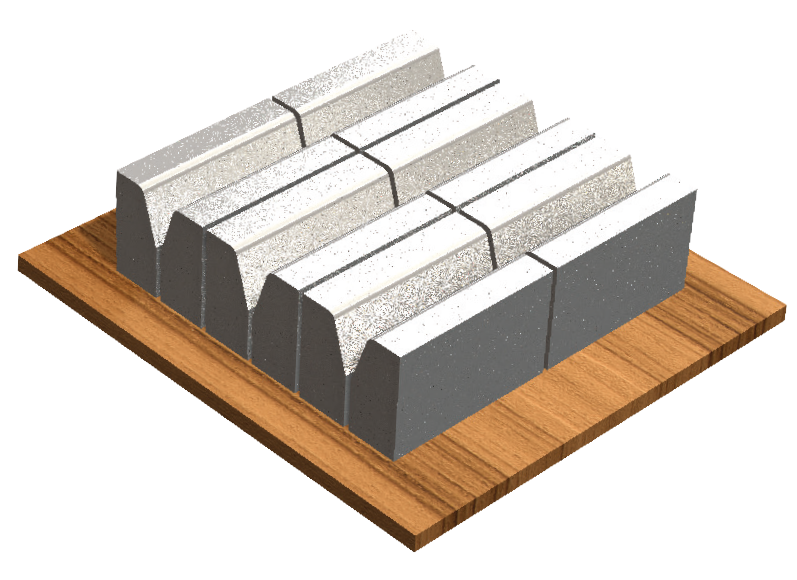

CURB STONE (12/15x50x30 cm)

| INSTALLMENT | CURBS PER PRESS | YIELD Pcs/h | YIELD M/Shift |

| 3036 | 1 | 150 | 9600 |