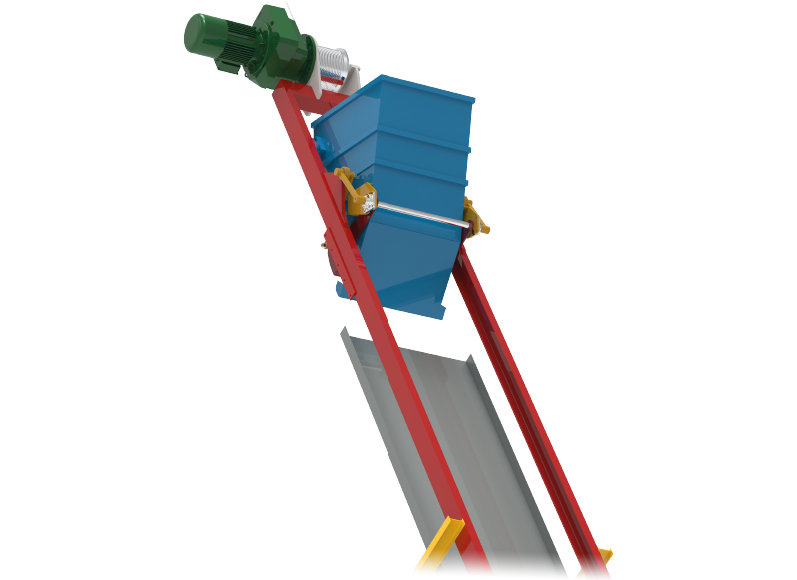

There is no more narrow area thanks to high angle of bucket elevation. Up to 90 degrees material elevation may be obtained with bucket skip solutions.

Skip Hoist

Batching Systems

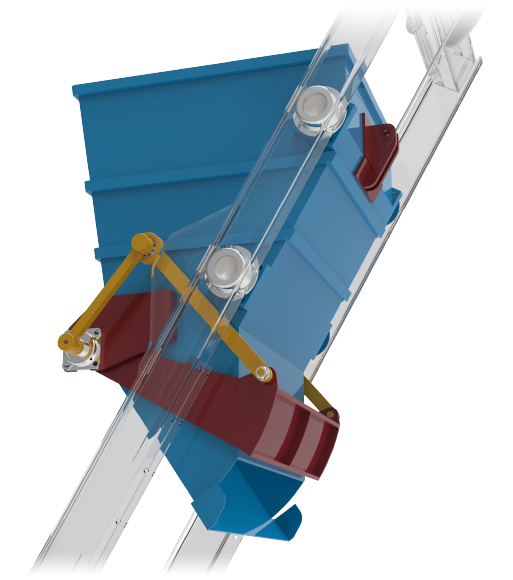

Revolutionary gate design that minimizes efficiency loss due to statics of skip hoist. There is no more narrow area thanks to high angle of bucket elevation.

The bucket sled takes over the stage when constrained spaces begin to hinder the useful factory layout. Compared to other transport solutions today, its working principle is based on very old methods. With its steepness of use that can increase up to 90 degrees, it continues to be the choice of businesses with small or sloping land. Although the mechanism and its maintenance are understandable, the necessity of periodic maintenance and constant safety awareness should not be overlooked. The gearmotors used are between 4 kW and 22 kW. Absolute braking system is used in reducers. Winding drums are manufactured with rope grooves to prevent the ropes from breaking.Self-lubricating hemp reinforced steel ropes are used. The preferred system for narrow spaces is used to transport aggregates to mixers. Bucket, rope and winding drum are used to form the system. For small systems, 250 lt buckets and the largest 2500 lt buckets are used.

The gearmotors used are between 4 kW and 22 kW. Absolute braking system is used in reducers. Winding drums are manufactured with rope grooves to prevent the ropes from breaking. Self-lubricating hemp reinforced steel ropes are used.

The preferred system for narrow spaces is used to transport aggregates to mixers. Bucket, rope and winding drum are used to form the system. For small systems, 250 lt buckets and the largest 2500 lt buckets are used.