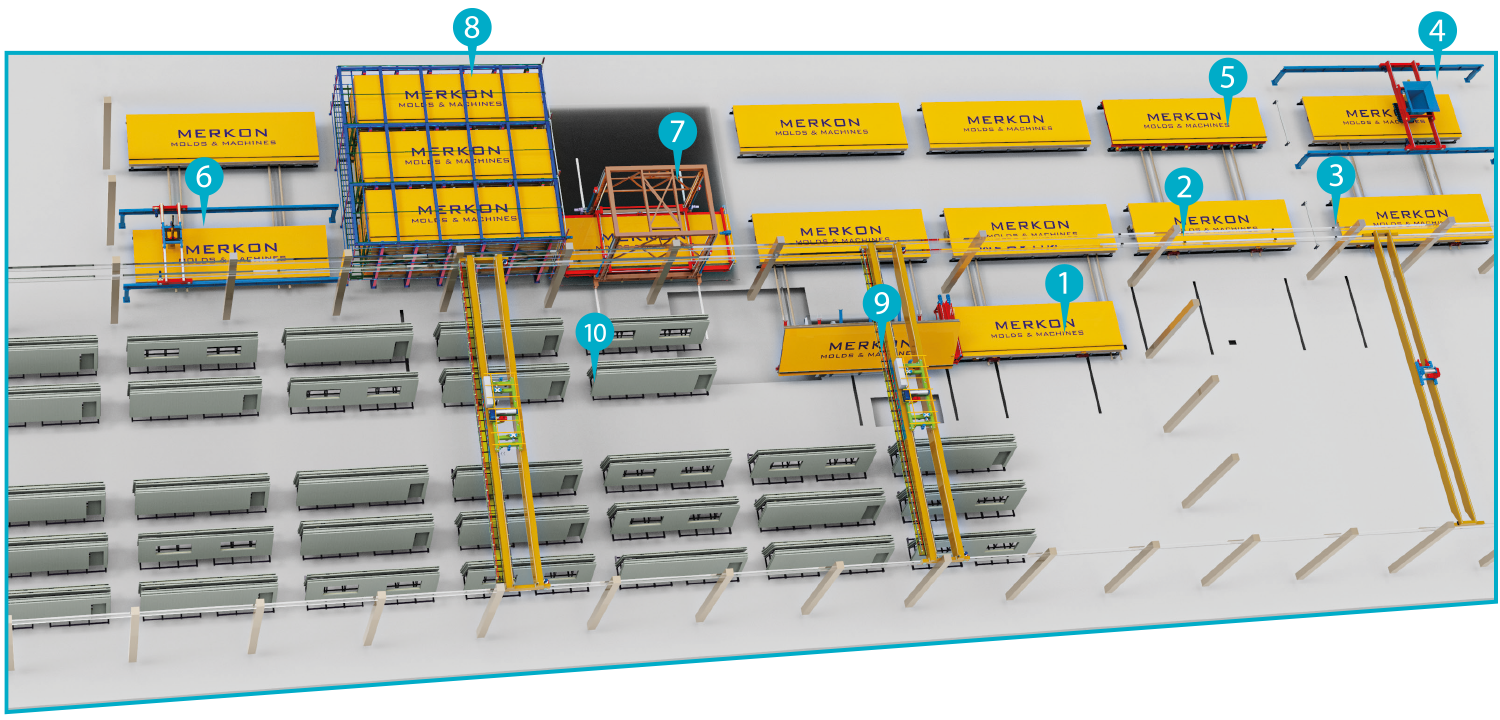

Solid Wall / Floor Slab /

Sandwich Panel Advanced Version

Precast

- Bed Checkup

- Mold Preparation

- Rebar Preparation

- 2 Axis Casting

- Insulation Application

- Facing Machine

- Casting Bed Elevator

- Curing Chambers

- Tilting Table

- Stocking Field

Cycle time is lowered by dividing tasks to more stations. Facing process is automized to match the cycle time. An elevator carries casting beds to individually separated curing chambers, where fully equipped with heat and humidity sensors to maintain optimal curing atmosphere. After correct curing duration, same elevator takes the beds out to make them continue along the line. Where next, they will be tilted up and products carried out to stock area by help of a crane.

| PRODUCT DIMENSIONS | Max Lenght (m) | Max Width (m) | Max Thickness (cm) | m² on Pallet |

| SOLID WALL / SOLID SLAB | 9 | 3 | 15 | 27 |

| SANDWICH PANEL | 9,5 | 3,5 | 25 | 33,25 |

| PRODUCTION CAPACITY | PALLETS PER HOUR | PER 20 HOUR DAY | DAILY YIELD m² (80% efficiency) | YEARLY YIELD (m²) (300 days) |

| SOLID WALL / SOLID SLAB | 2 | 40 | 864 | 259200 |

| SANDWICH PANEL | 1 | 20 | 532 | 159600 |

| Auto Rebar SOLID WALL / SOLID SLAB | 3 | 60 | 1296 | 388800 |

| Auto Rebar SANDWICH PANEL | 1,5 | 30 | 798 | 239400 |